CALL TO ORDER 903-262-9502

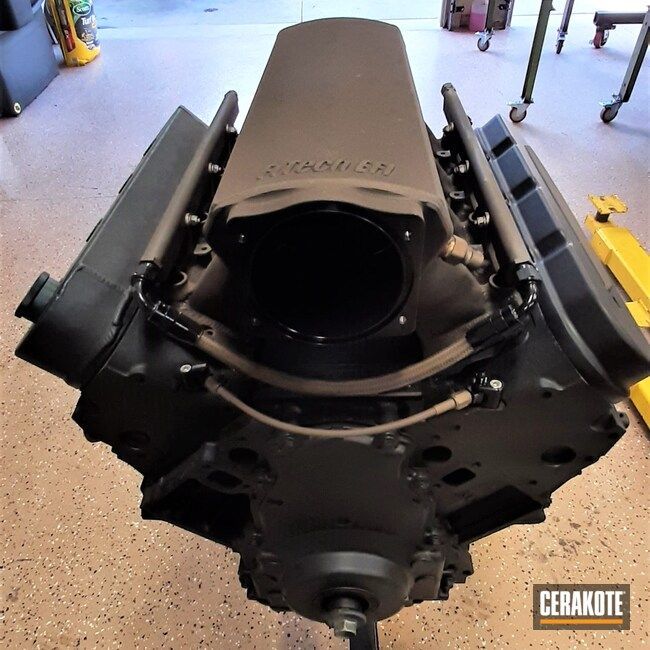

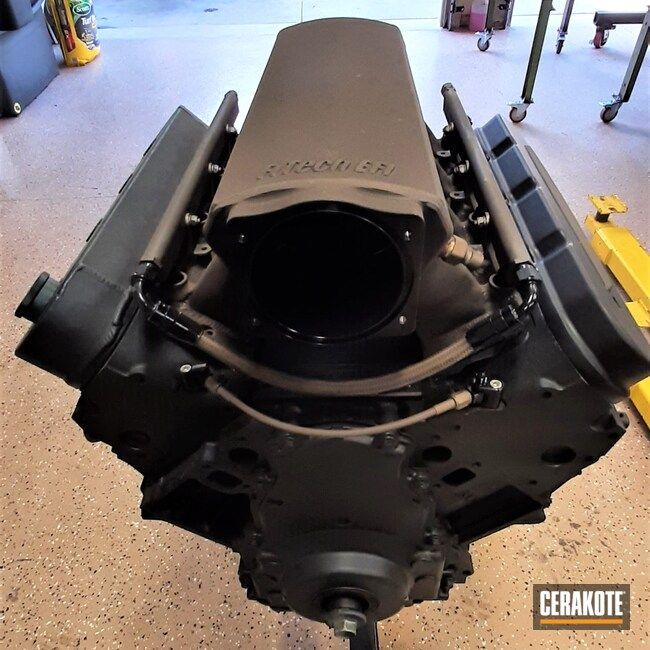

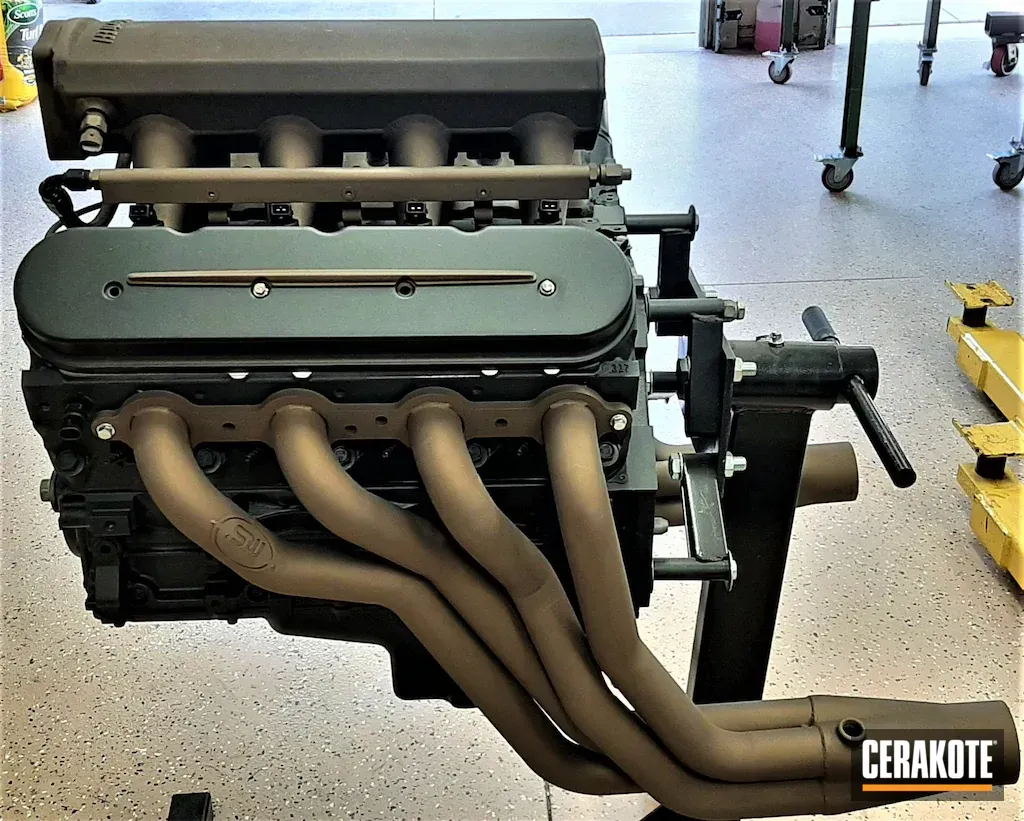

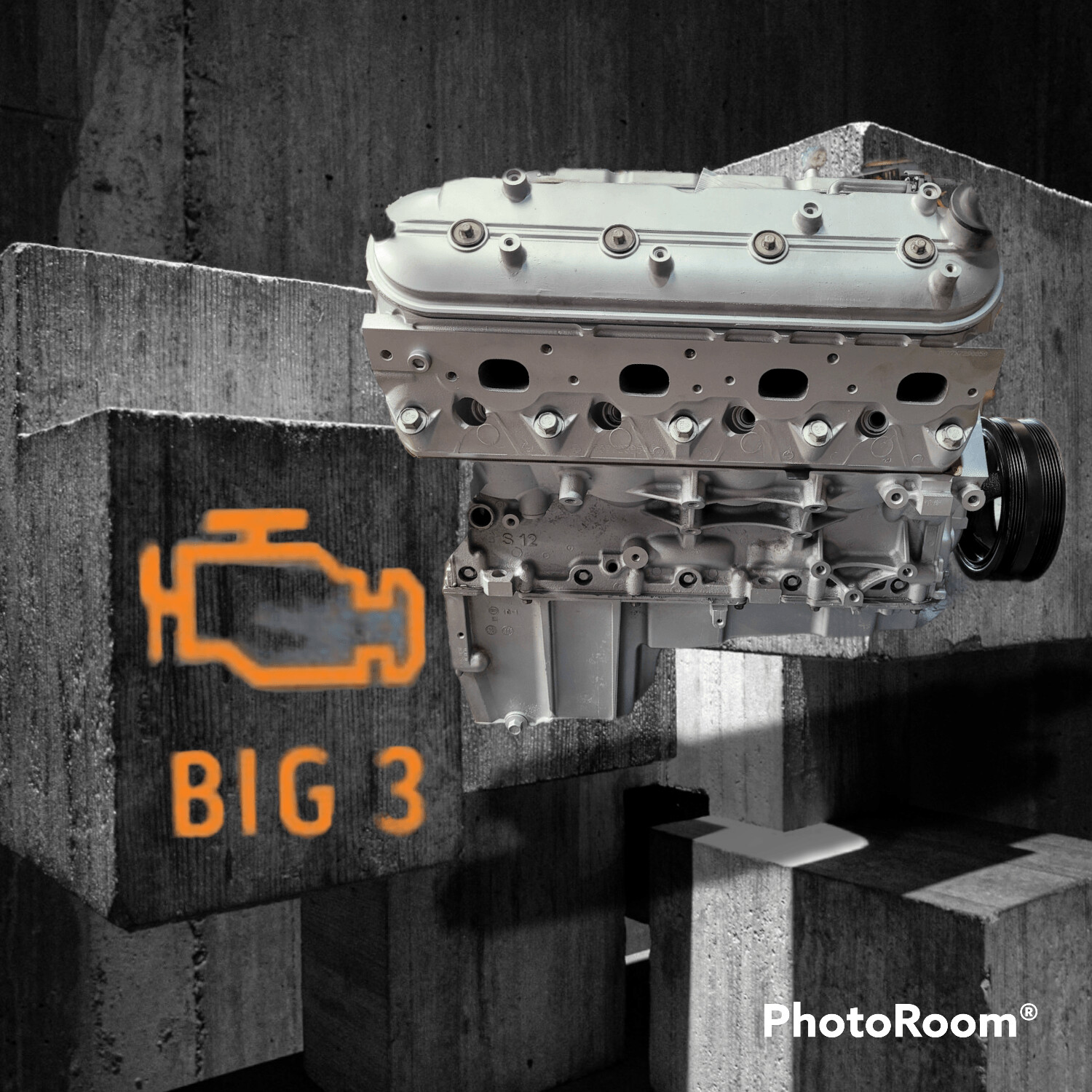

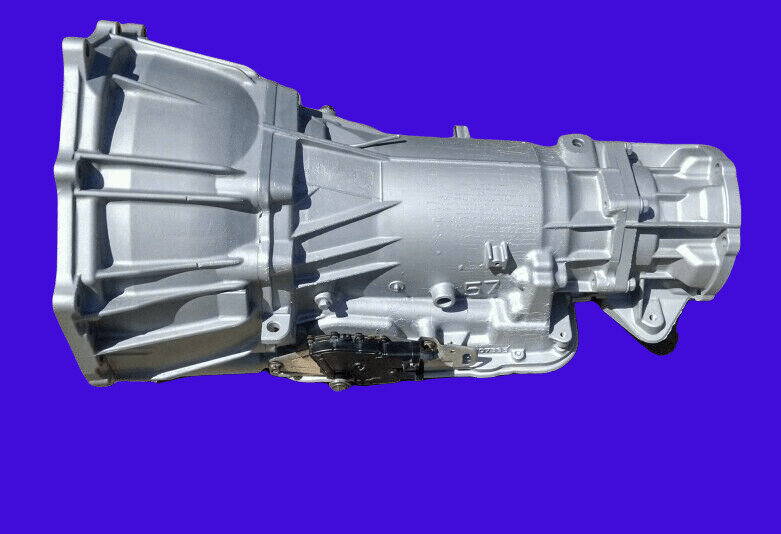

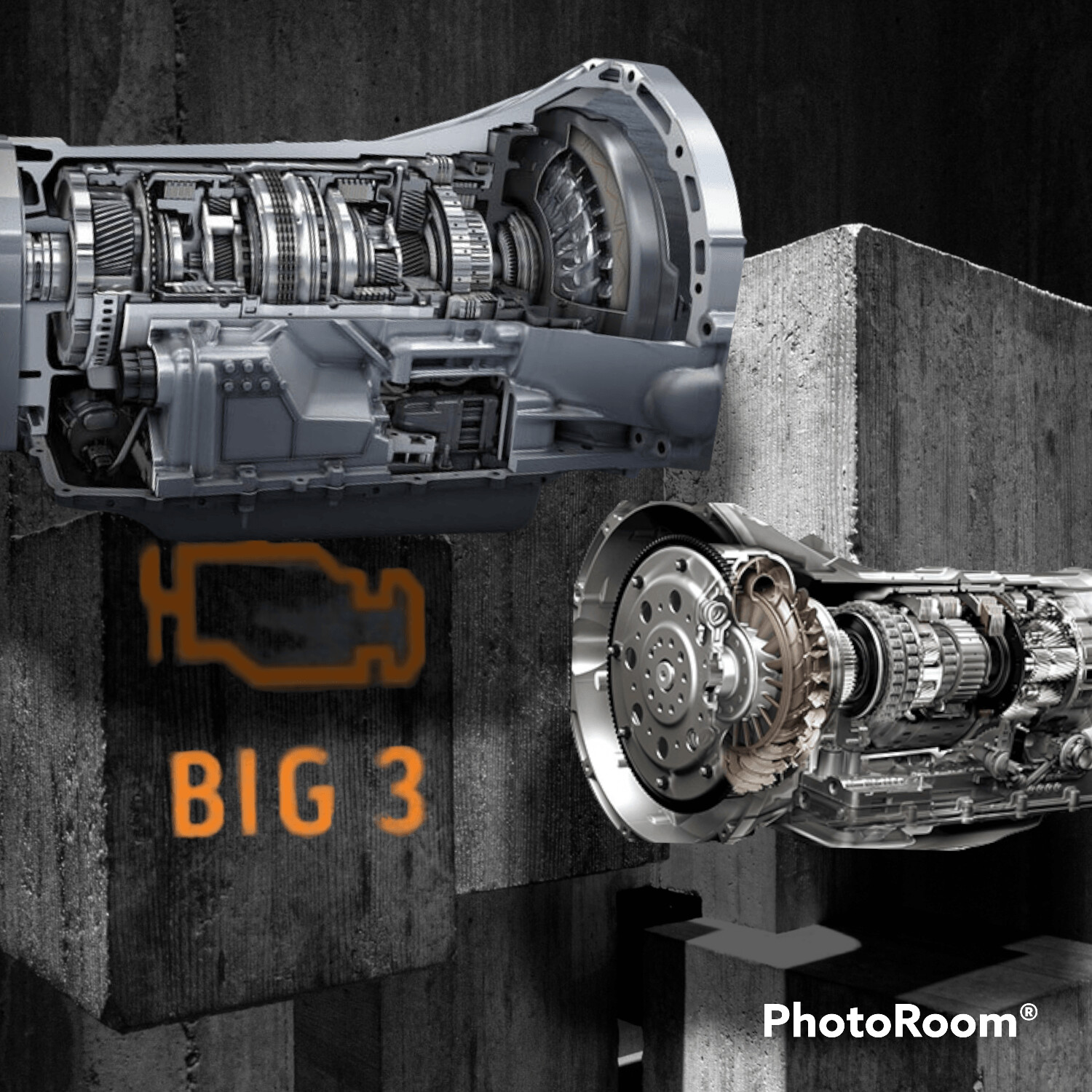

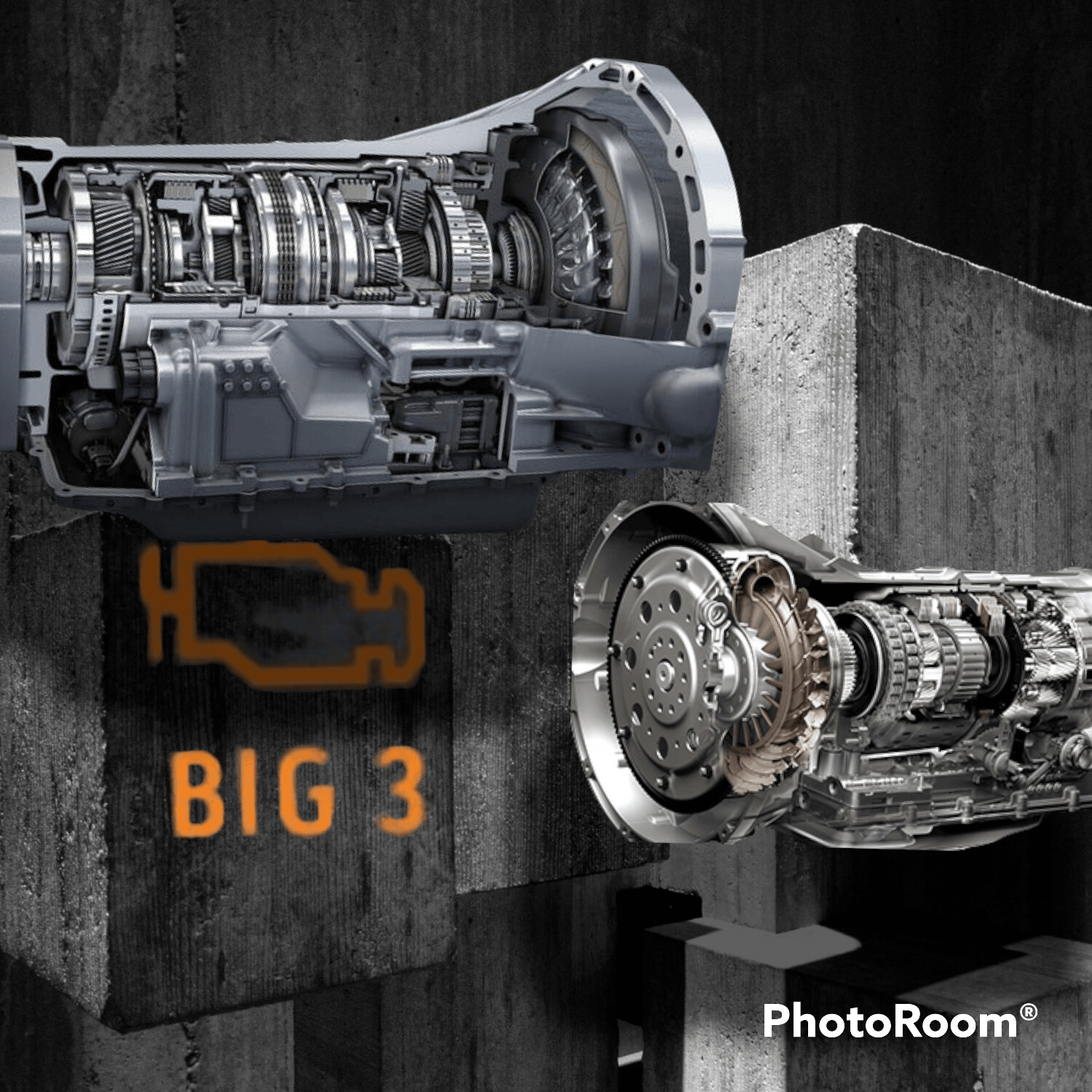

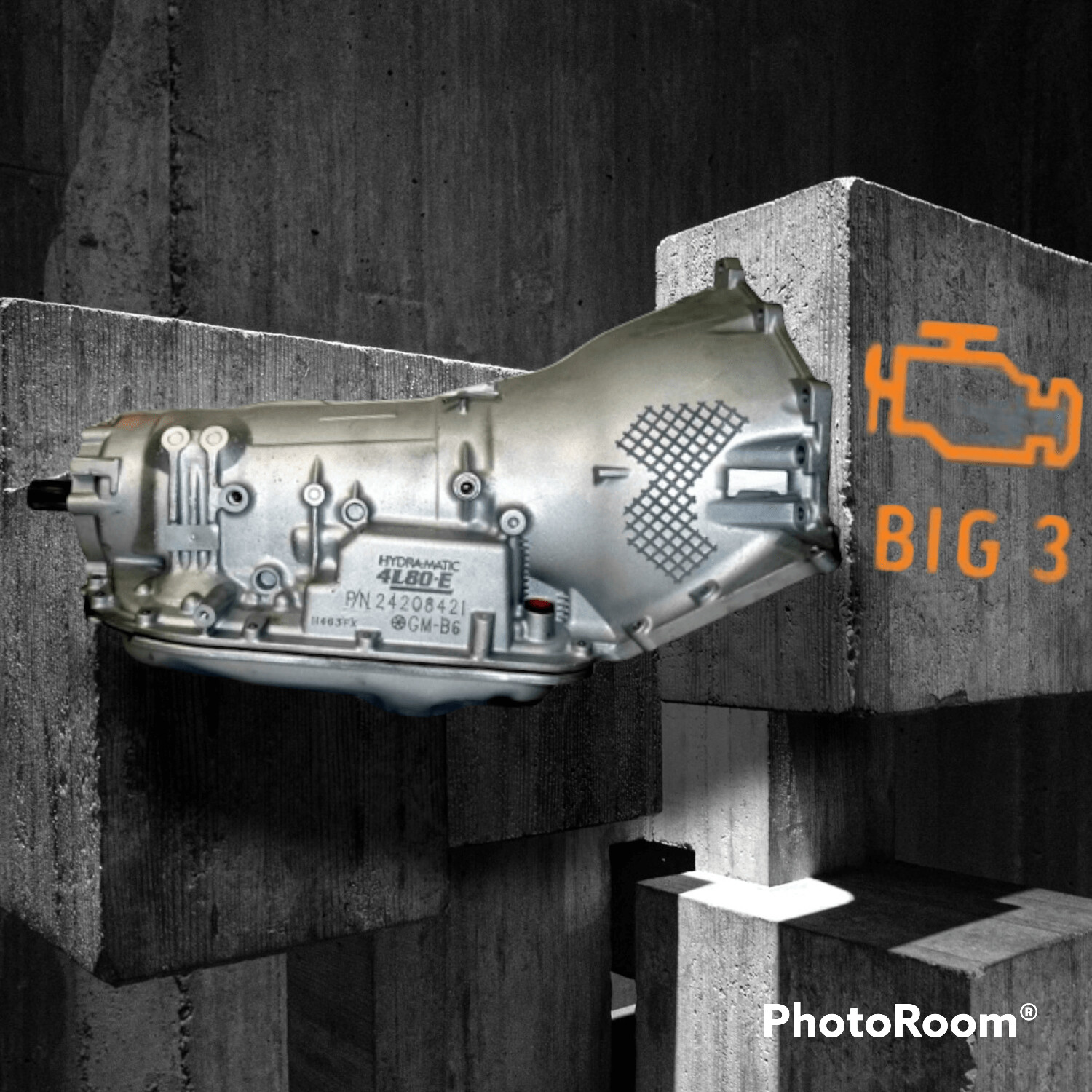

CERTIFIED REMANUFACTURED AND RECYCLED ENGINES AND TRANSMISSIONS

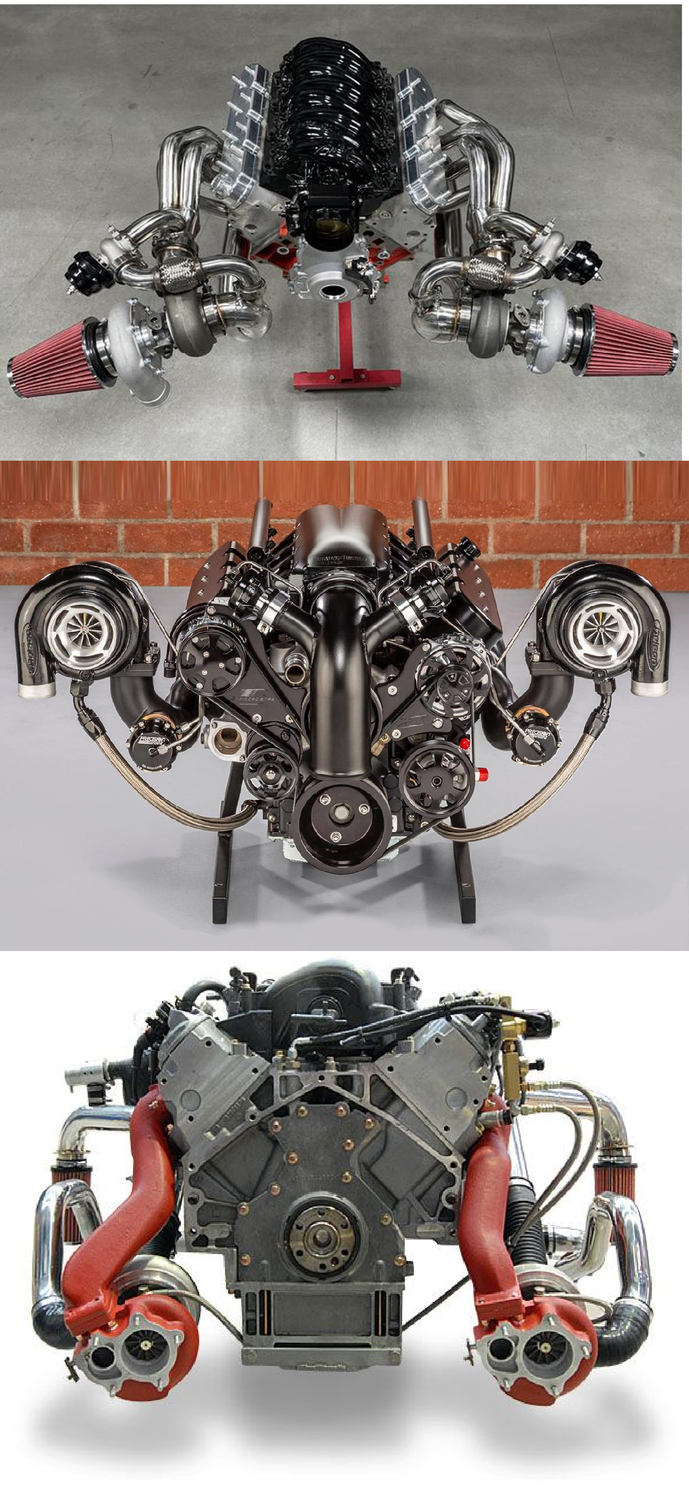

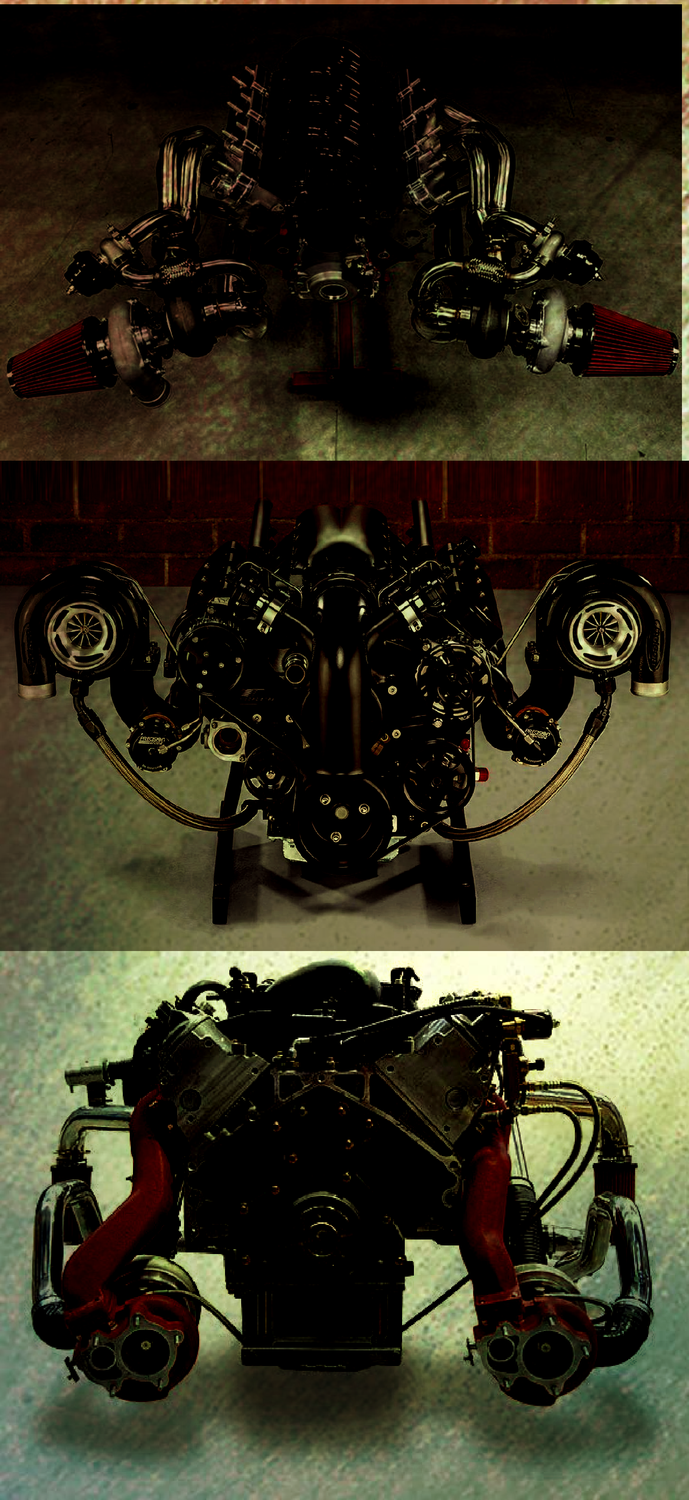

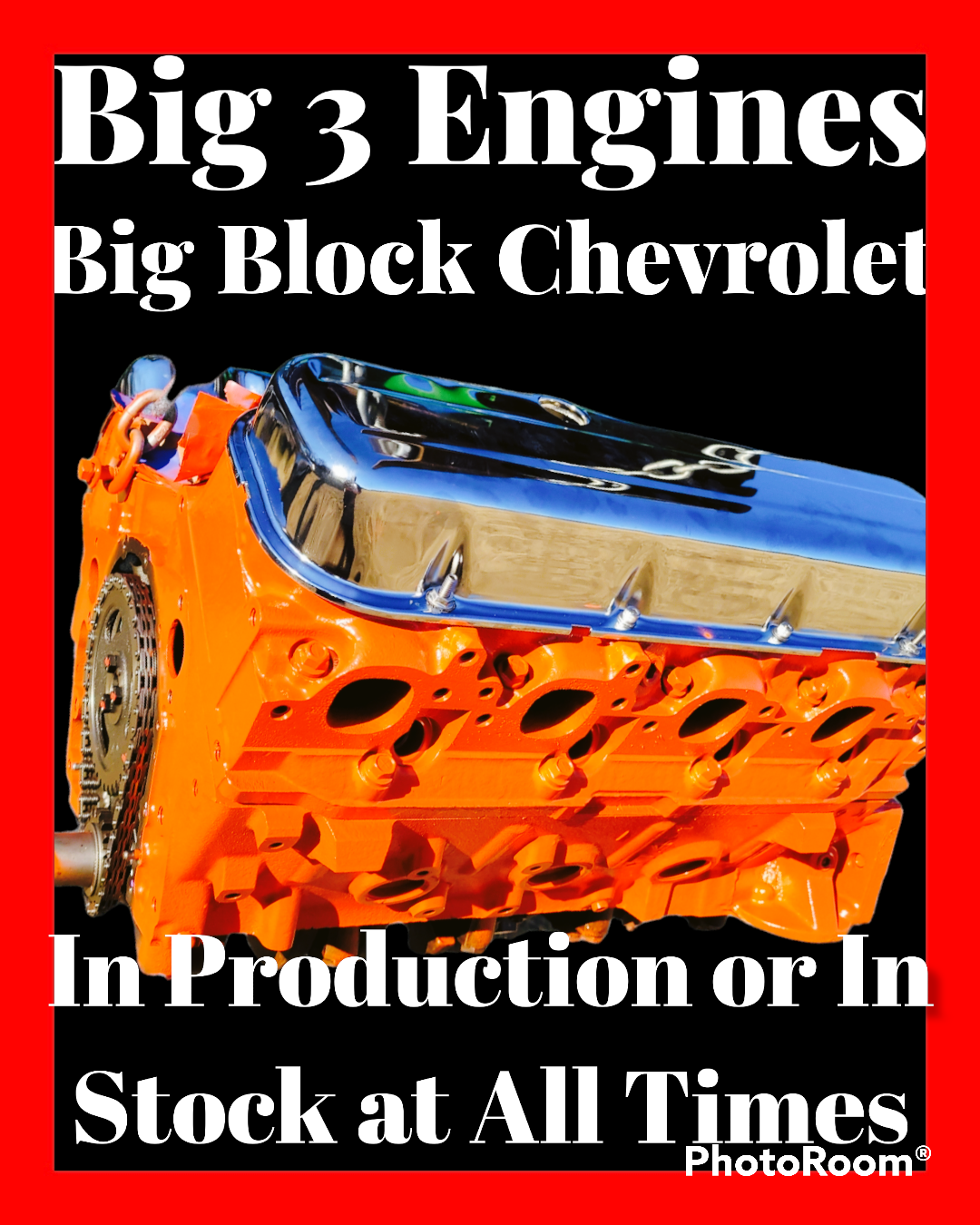

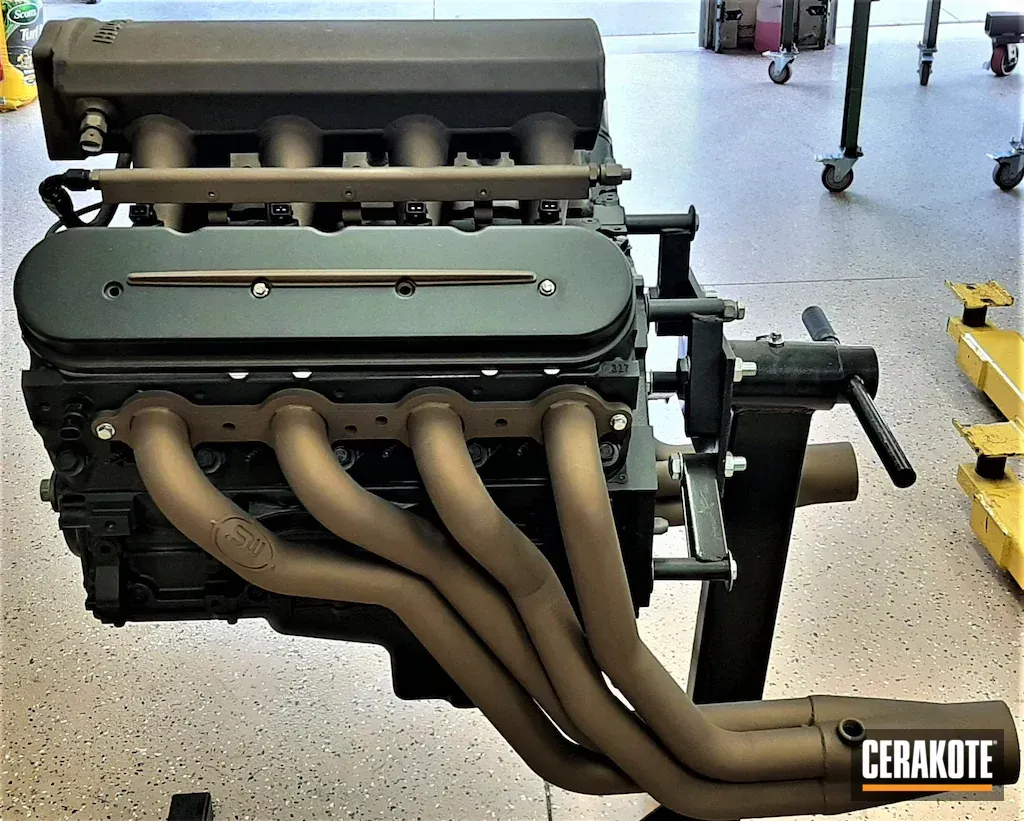

HEAVY DUTY AND PERFORMANCE DIESEL AND GAS

COMMERCIAL AND COMPETITION

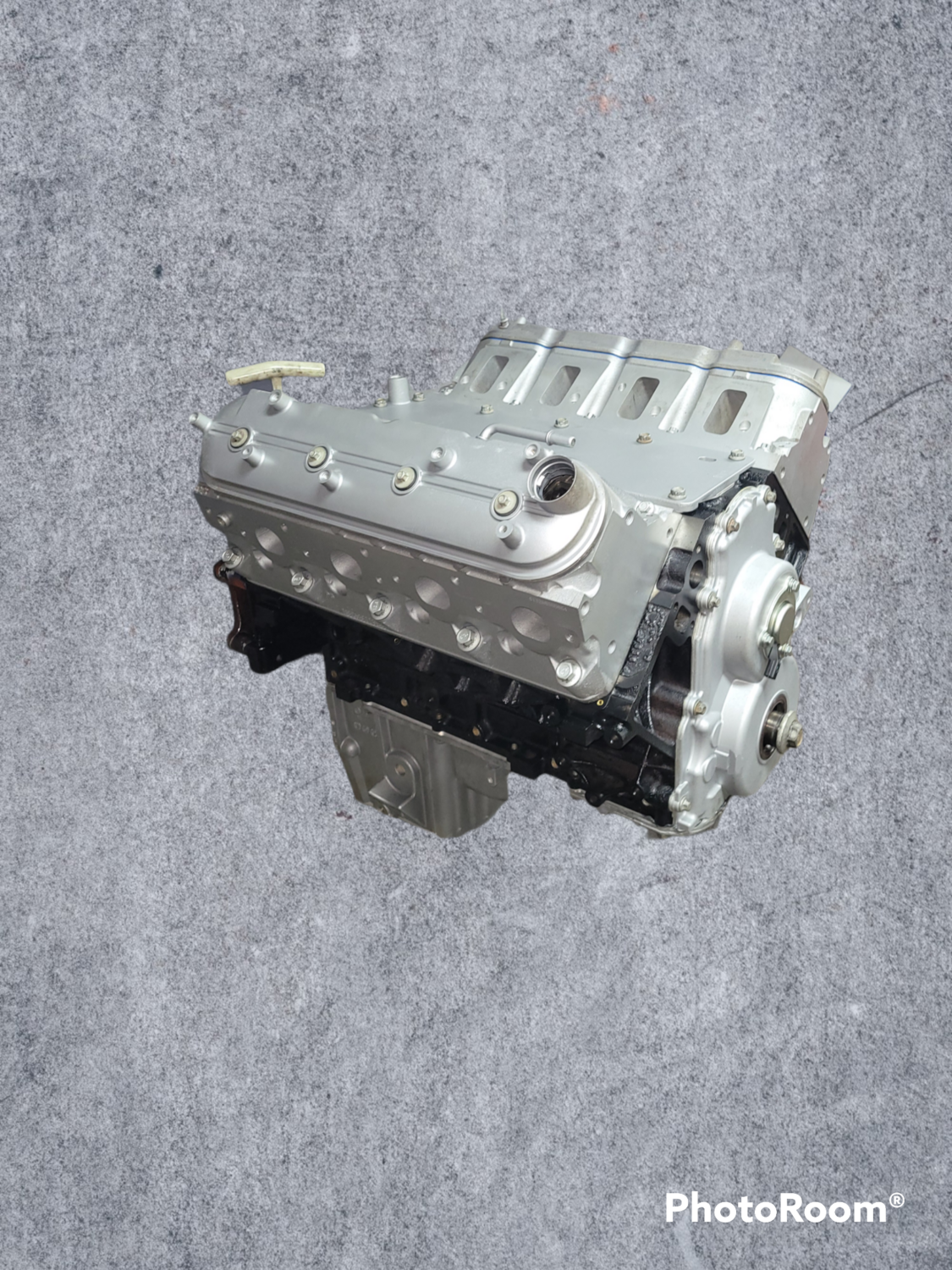

CLASSIC ENGINE RESTORATION

(903)262-9502

10 AM - 5 PM CENTRAL TIME

MONDAY - FRIDAY

48 State Delivery

INSTALLATION AVAILABLE IN EAST TEXAS

Current Specials

Many more Available. Call the office to find the Engine or Transmission that you need!

903-262-9502

Privacy Policy

CALL FOR HELP WITH YOUR ORDER 903-262-9502

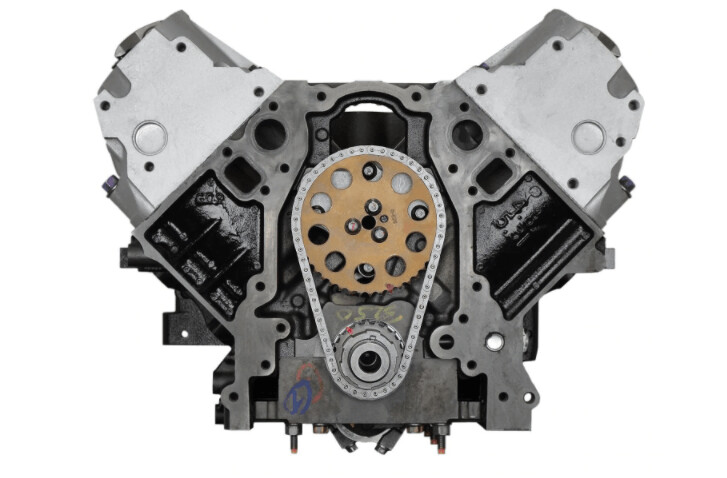

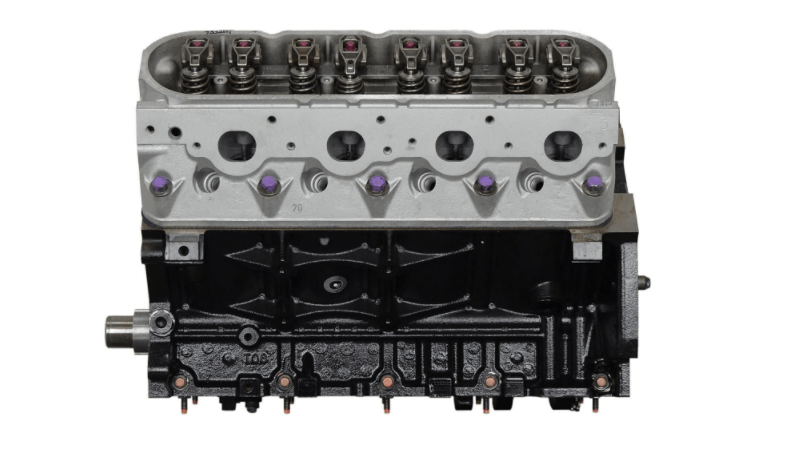

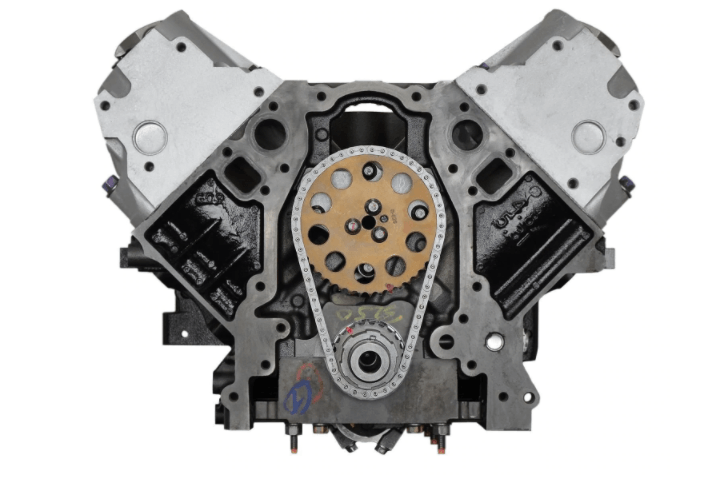

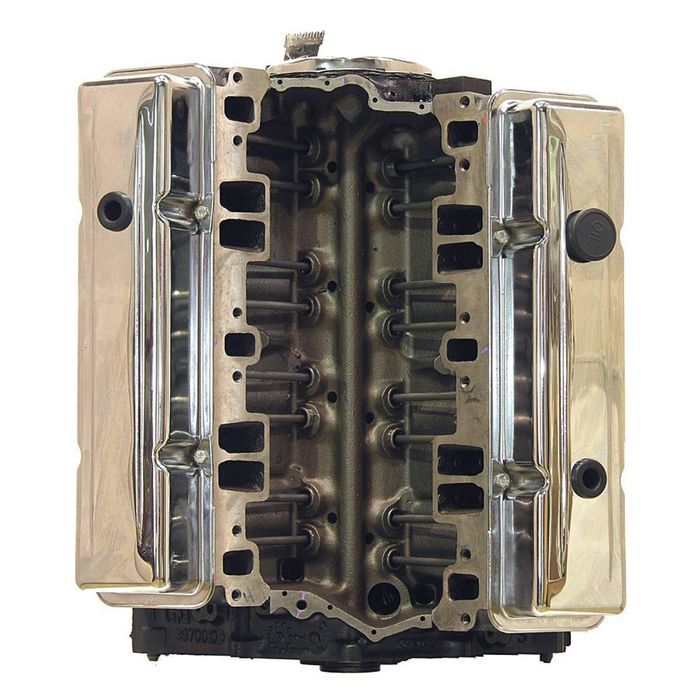

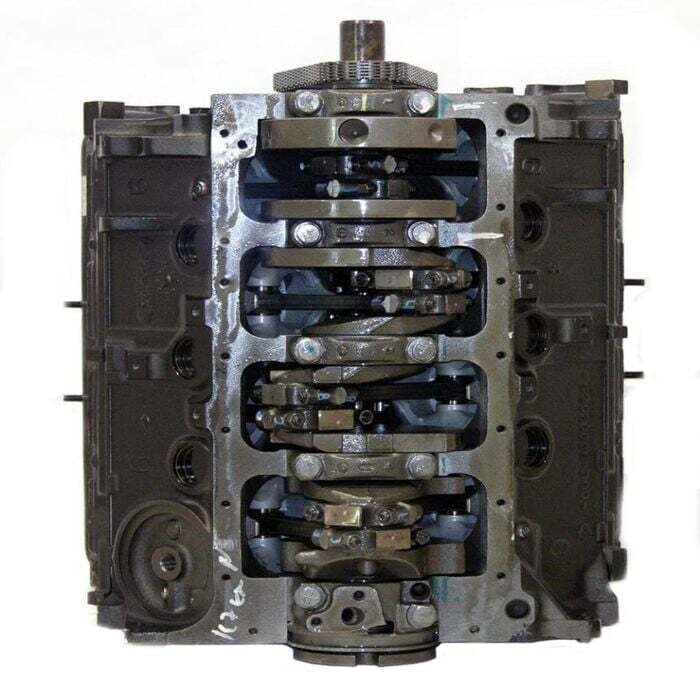

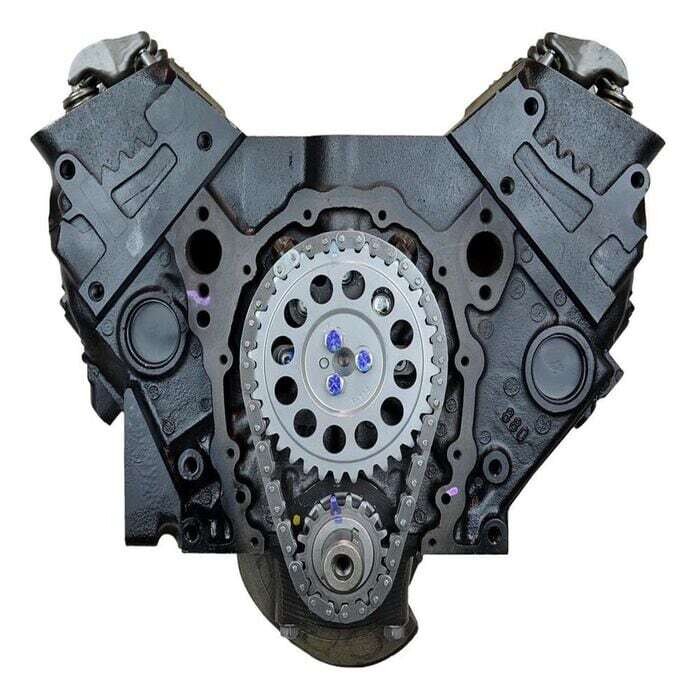

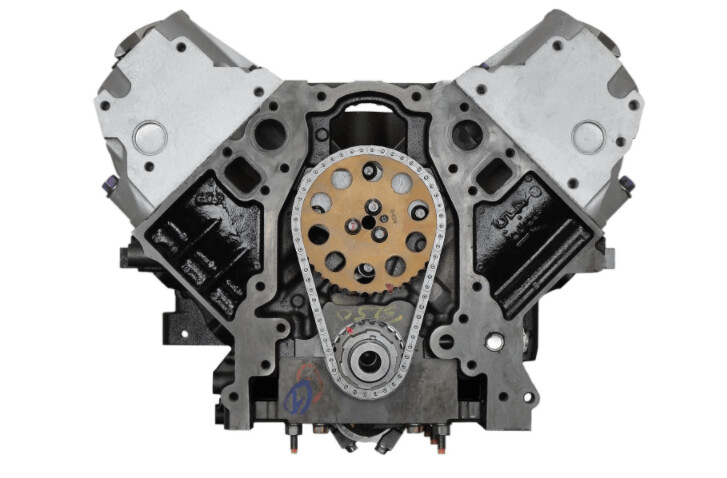

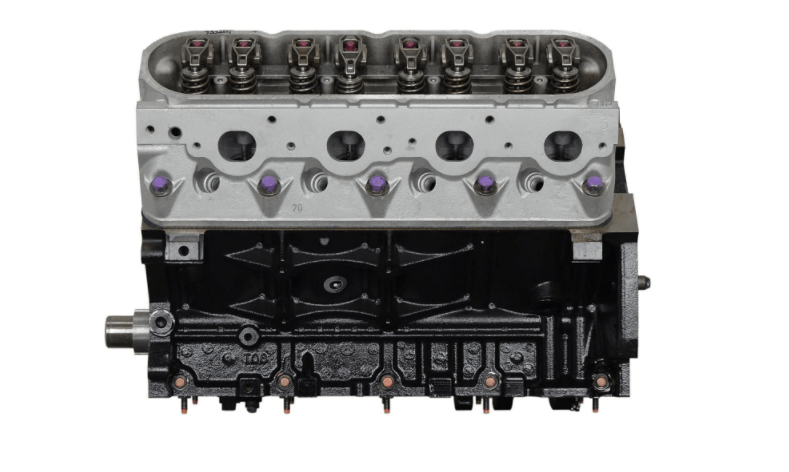

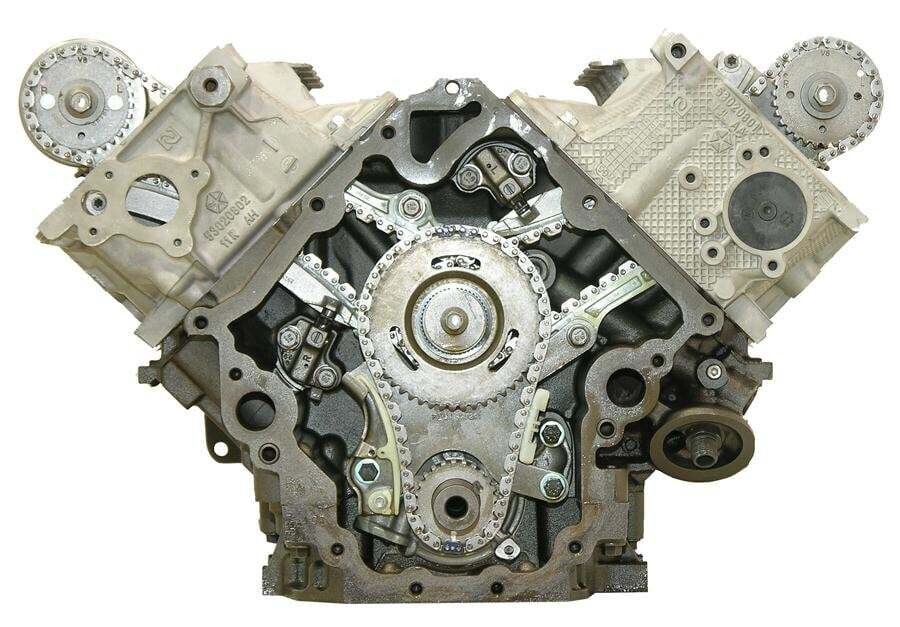

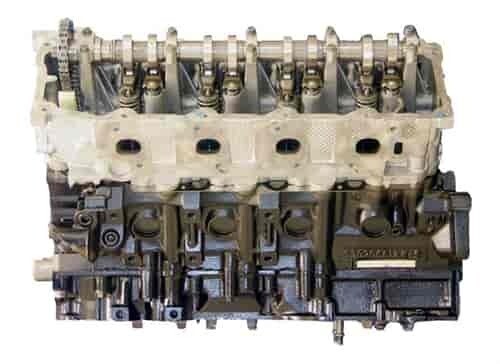

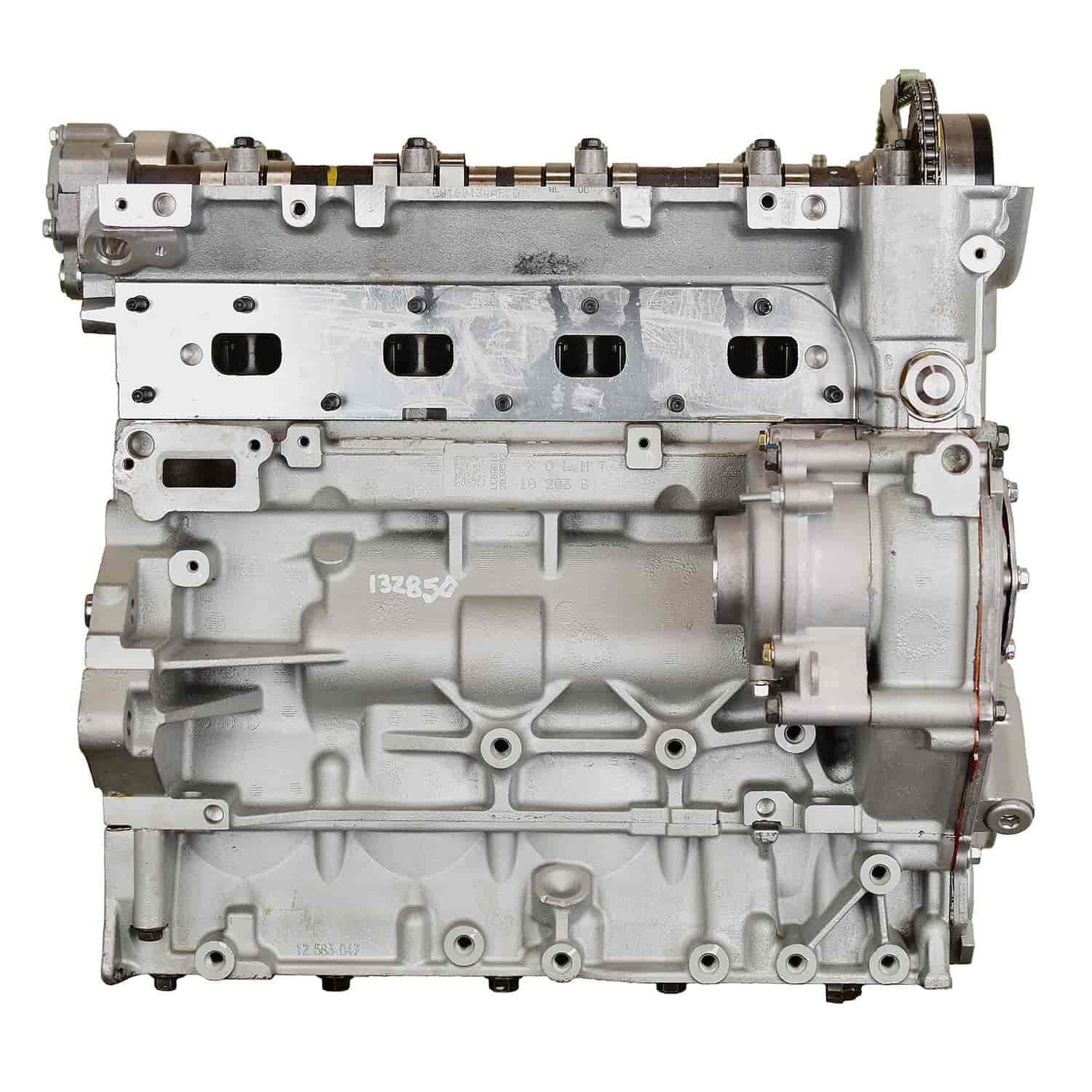

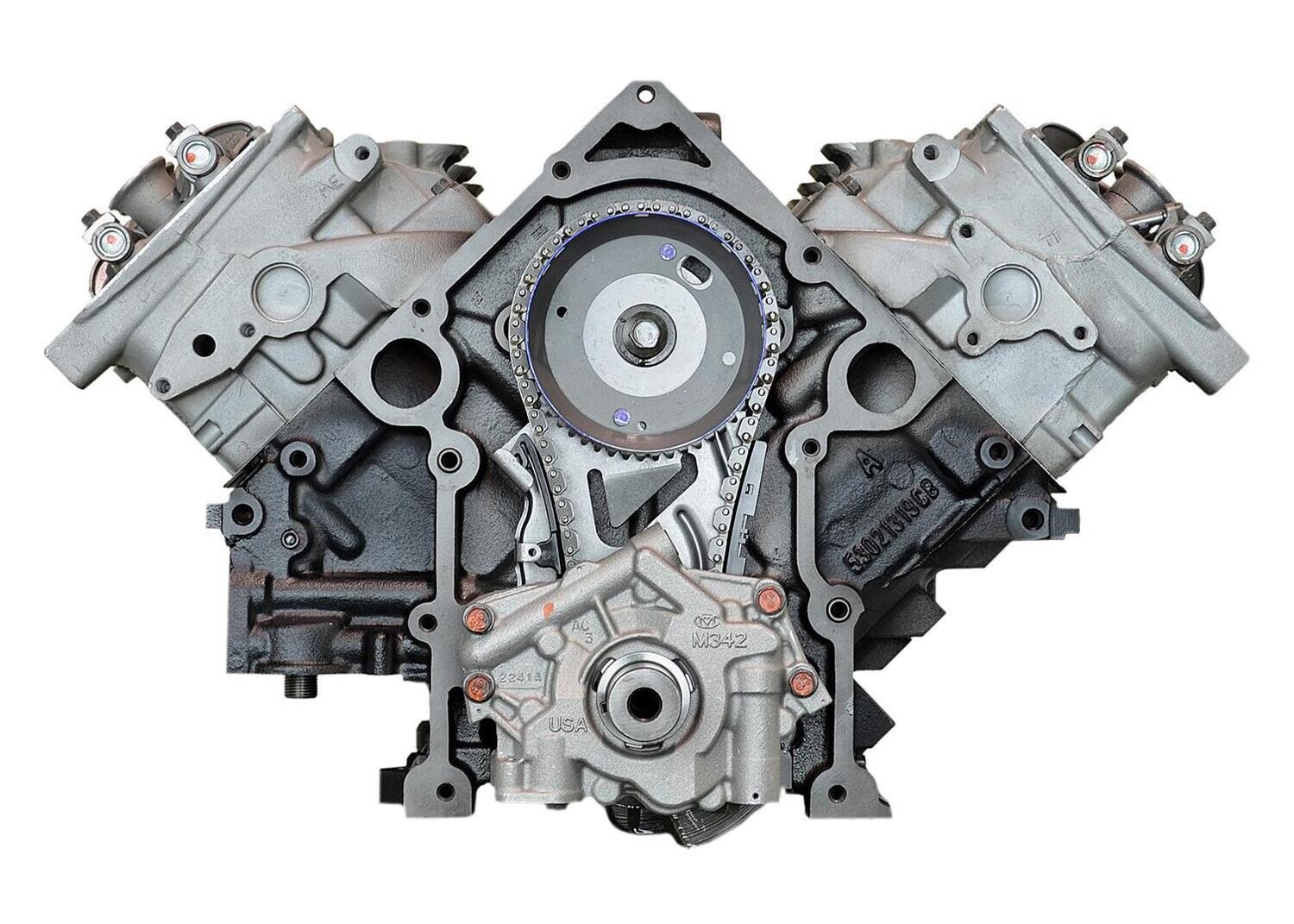

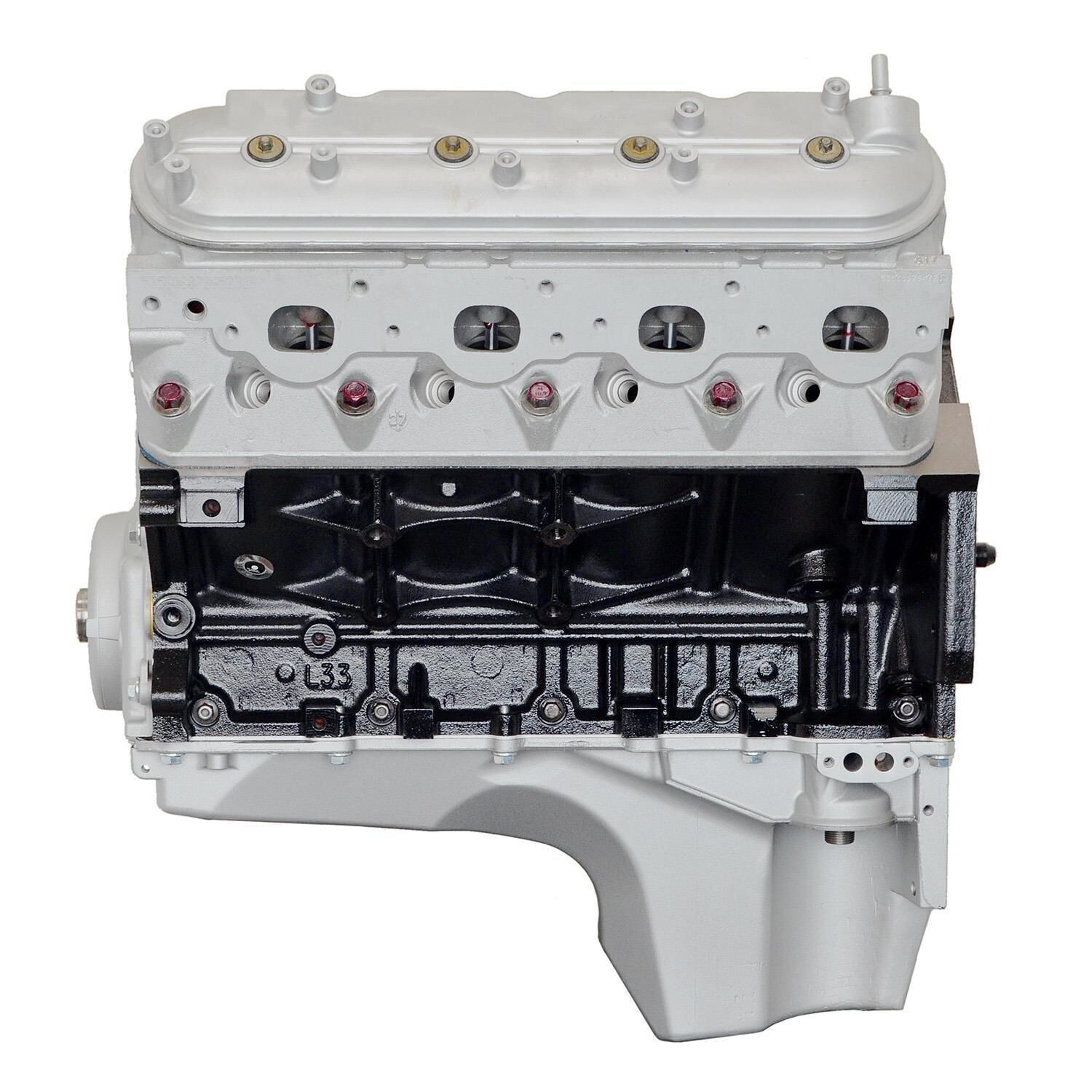

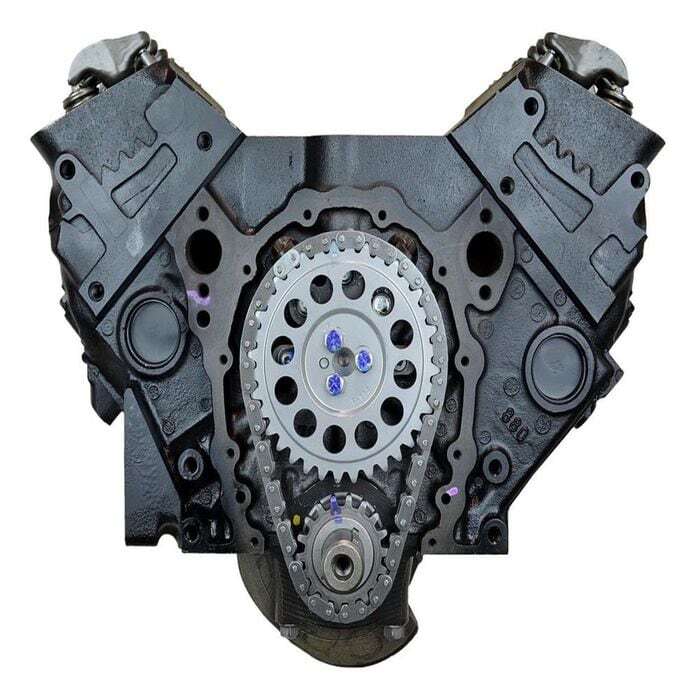

All remanufactured engines are Carefully Assembled. Blocks, heads, rods, crankshafts and camshafts are thoroughly cleaned before assembly to remove all contaminants which can lead to early component and engine failure.

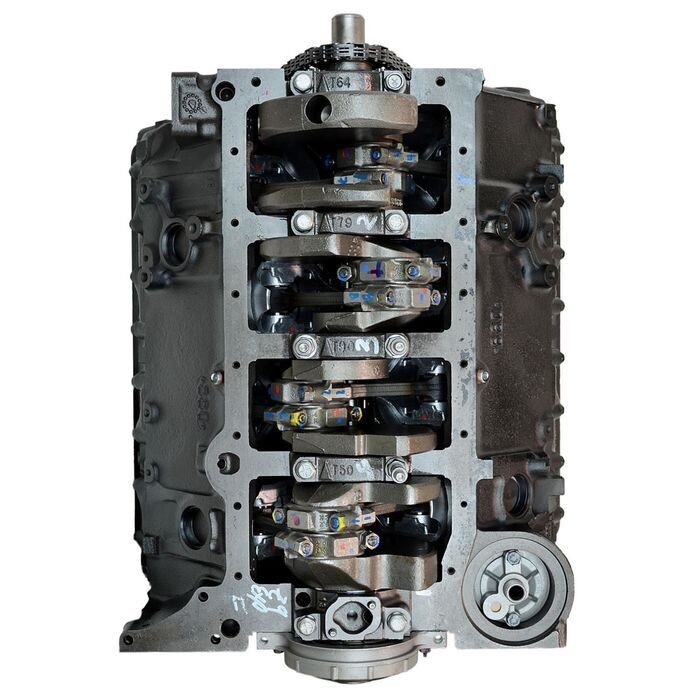

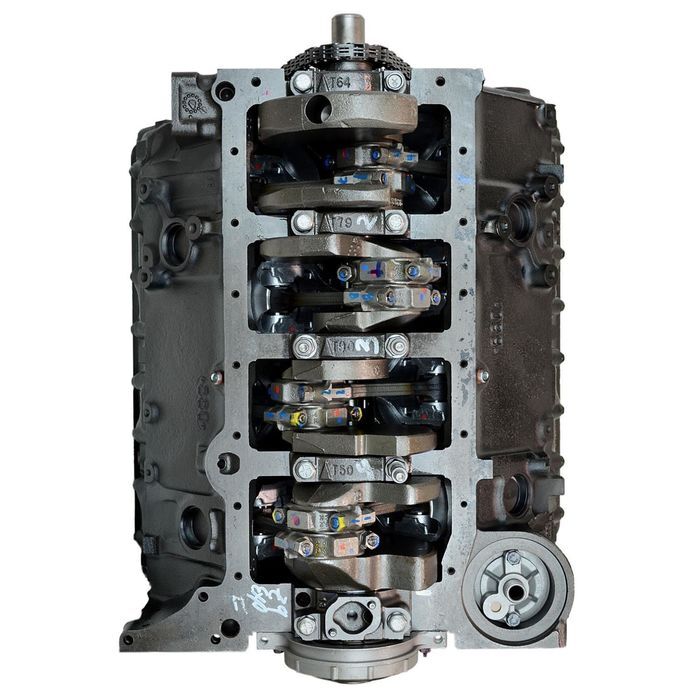

All remanufactured engines are Carefully Assembled. Blocks, heads, rods, crankshafts and camshafts are thoroughly cleaned before assembly to remove all contaminants which can lead to early component and engine failure. Crankshafts are precision machined to exact tolerances, polished & magnafluxed, then inspected by our quality control department. These are matched with new premium bearings for long life.

Crankshafts are precision machined to exact tolerances, polished & magnafluxed, then inspected by our quality control department. These are matched with new premium bearings for long life.